Meguiar's Professional Series: Using A Rotary Polisher

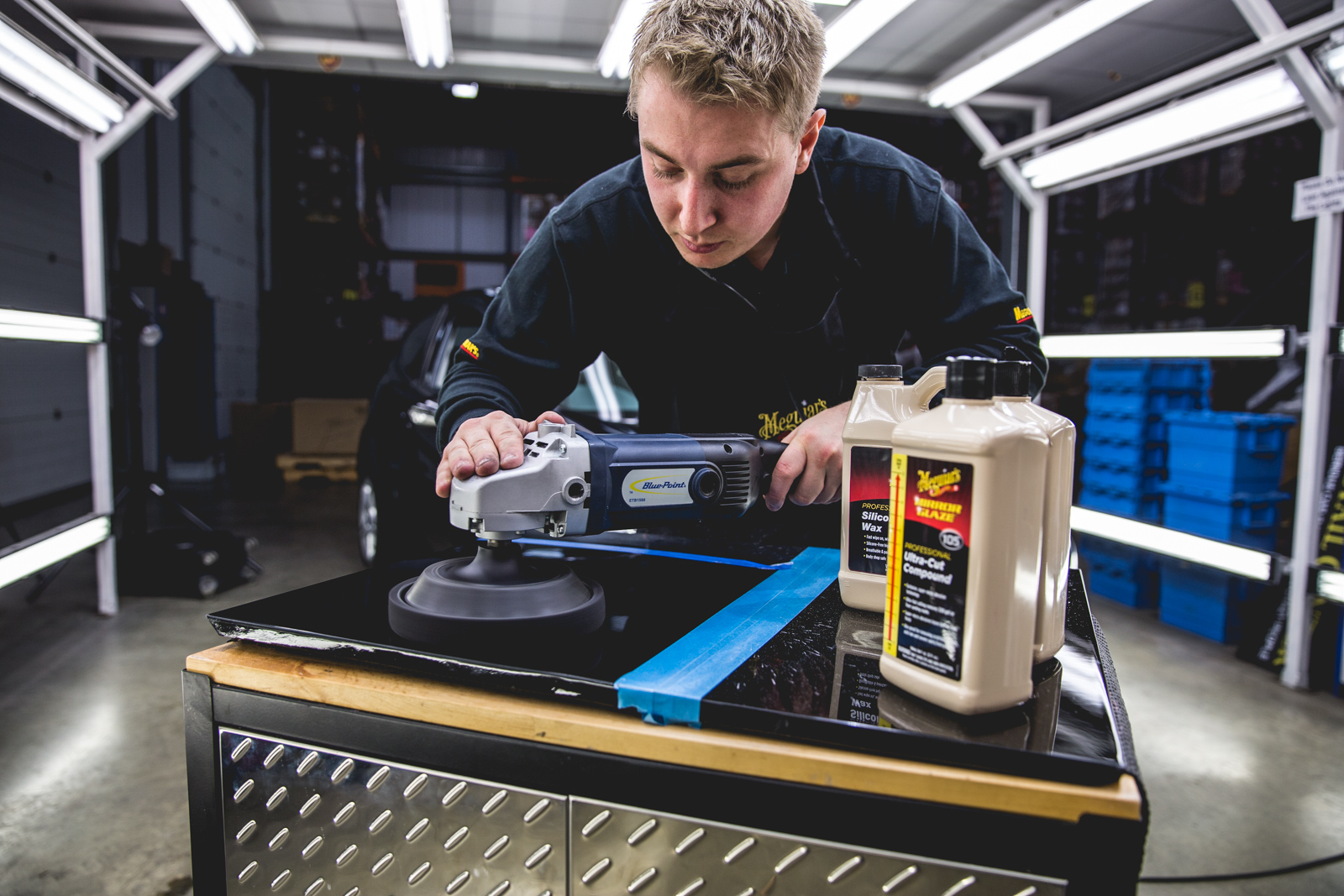

For part 3 of our Professional Series spotlight, we’re taking a closer look at the world of rotary polishers and the products Meguiar’s offers specifically for their use.

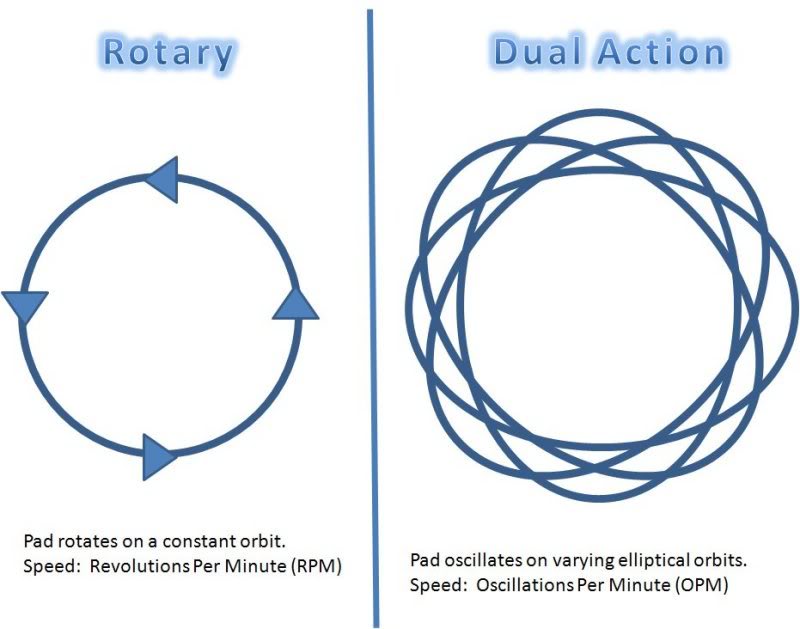

Rotary polishers work very differently to a DA (dual action) polisher. With a rotary, the spinning motion is fixed on a single axis whereas a DA features dual action oscillation as demonstrated in the graphic below.

The main benefit of a rotary compared to a DA is the speed and cut it provides on even the hardest paints – an essential for industry professionals where time is limited and you’re exposed to all kinds of paints on a daily basis. On the downside, incorrectly using a rotary can result in serious damage to your car’s paintwork (otherwise known as burning) due to the heat caused unlike a DA system.

Both systems are intended to revive, refine and protect paintwork but require very different techniques to achieve the desired results. Throughout this blog post we’ll be showing you a step-by-step guide on the Meguiar’s Professional Series products designed for rotary use, and how to apply them correctly to avoid damaging your paint. Let’s start with 105 Ultra Cut Compound…

Meguiar’s 105 Ultra Cut Compound – just like 205 Finishing Polish and 305 Wax – is a silicone-free product specifically designed for bodyshop use. The reason behind this is to remove the risk of ‘fish eyeing’ – an unwanted effect caused by silicone contaminating paint and reacting during the initial painting process. Once painted and protected, this risk is no longer an issue (allowing silicone to be used within our consumer range).

When applying 105 Ultra Cut Compound, your arm movement should be increased to ensure that the machine is always kept moving. Do not move in a slower motion like when using a DA system, and never let it dwell in one place otherwise the heat build-up will quickly damage and burn the paintwork.

Like the consumer range, Meguiar’s offers several discs for application – a red cutting pad, a yellow polishing pad and a black finishing pad. Prepping the pad before application is essential, and the compound should be spread evenly across it before working on a panel.

When used correctly, M105 quickly revives paintwork after colour sanding bringing life and shine back into the surface. Use a clean microfibre cloth to remove any excess product when finished, and if need be go over the panel with a second pass.

For the polishing process, follow the exact same steps as the initial cutting – this time using Meguiar’s M205 Ultra Finish Polish on a yellow Meguiar’s polishing pad.

Ensure the pad is completely covered before quickly and evenly applying the finishing polish in a back and forth motion. M205 will remove any hazing left from the compounding stage, leaving the paintwork with a deep and shiny gloss.

Paintwork brought up to the designed glossy finish can now be protected with Meguiar’s M305 Silicone Free Wax. Using the Meguiar’s black polishing pad on the rotary, apply the wax evenly onto the pad before making a final pass over the panel ensuring the application is kept as even as possible.

Leave the wax to cure for just a few minutes before removing with a clean microfibre cloth. If you’re unsure when to remove the wax, run your finger over the paint’s surface – if a clear line is left within the paint it’s safe to be removed. The end result is a spectacular finish and protection on even the freshest paintwork!

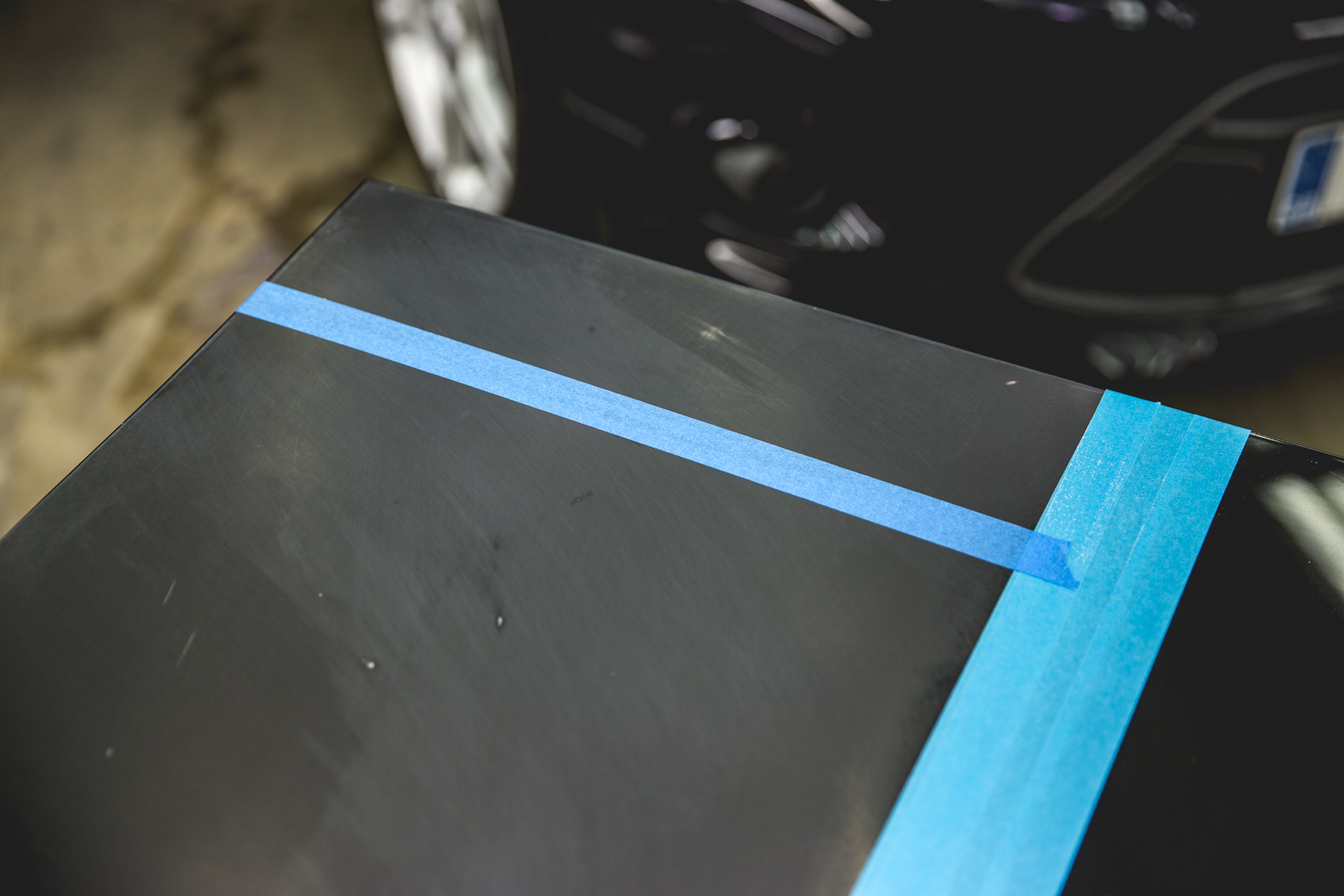

Using a rotary polisher definitely isn’t for beginners, and if used incorrectly can cause serious damage to your car’s paintwork. If you are interested in learning to use a rotary, Meguiar’s recommends practicing on a painted panel like the one used in this blog post before taking on your car’s paintwork. If you’re unsure whether a rotary system is right for you, we strongly recommend using our DA system instead to achieve the same high-quality results without the risk of paint damage.